From raw steel to finished perfection, every SurgiQat tool passes through these essential stages and the hands of 100+ skilled professionals. Each stage includes multiple precision steps to ensure excellence. This is how we've maintained our reputation for quality since 1990.

Design & Customization

We begin every project by understanding your specific needs and translating them into precision blueprints.

Design Development

Our experienced designers create detailed technical drawings and 3D models that capture every specification of your desired tool.

Custom Modifications

Whether you need specific dimensions, ergonomic adjustments, or unique features, we adapt our designs to match your brand requirements.

Client Approval

We share design prototypes and samples for your review before moving into full production, ensuring complete alignment with your vision.

Material Selection

Quality tools begin with quality materials. We source only premium-grade steel that meets international standards.

Steel Sourcing We use high-carbon Japanese steel and surgical-grade stainless steel known for durability, sharpness retention, and corrosion resistance:

- ATS-314 – Premium Japanese steel with exceptional edge retention

- VG-10 – High-quality stainless steel with excellent corrosion resistance

- 440C – Surgical-grade steel for hardness and rust resistance

- 8CR – High-carbon chromium steel balancing sharpness and toughness

- 420 – Versatile stainless steel with good corrosion resistance

- 3CR13 – Economical stainless steel for standard-grade tool

- AND MANY MORE OPTIONS

Material Testing Every batch undergoes rigorous testing to verify hardness, composition, and structural integrity before production.

Traceability We maintain complete documentation of material origins and specifications, ensuring consistency across all orders.

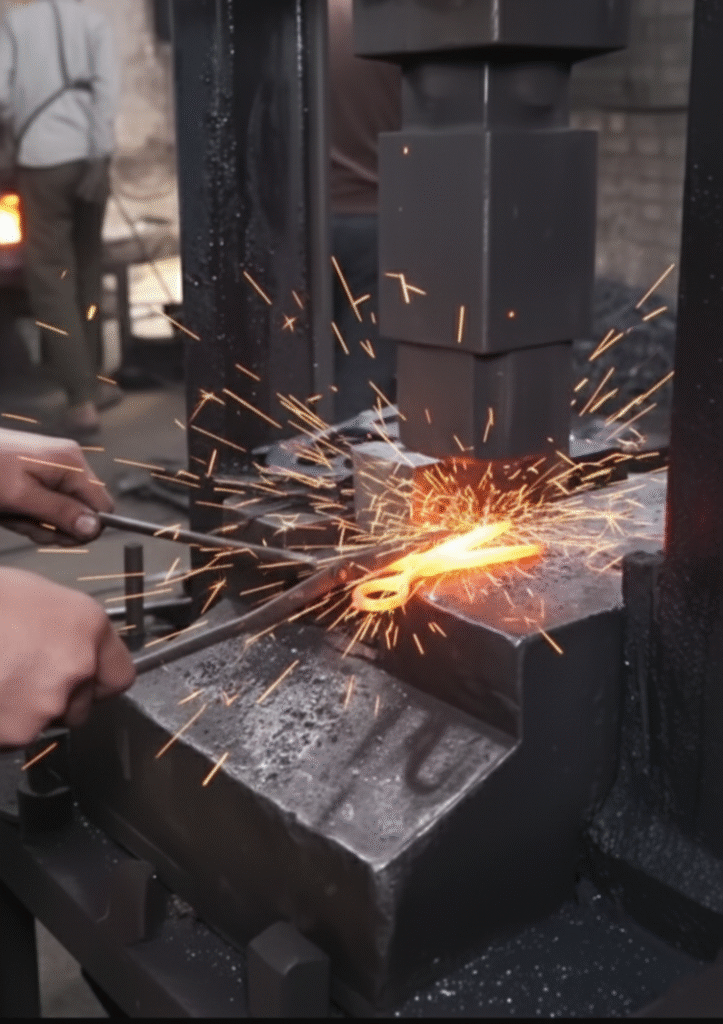

Forging

Raw steel is heated and shaped under intense pressure to form the basic structure of each instrument.

Heat Treatment Steel is heated to precise temperatures in controlled furnaces, making it malleable for shaping while preserving its core strength.

Precision Molding Skilled craftsmen use hydraulic presses and specialized dies to forge the steel into scissor blades, razor frames, or tool bodies.

Structural Integrity The forging process aligns the steel’s grain structure, creating tools that are stronger and more durable than stamped alternatives.

Drilling

Strategic holes and cavities are precisely drilled to create mounting points, finger rests, and functional openings.

CNC Precision Drilling Computer-controlled machines ensure every hole is drilled at exact depths and angles, guaranteeing perfect assembly alignment.

Finger Rest Formation Ergonomic finger holes in scissors are carefully drilled and positioned for maximum comfort during extended use.

Quality Verification Each drilled component is measured to ensure dimensional accuracy before proceeding to the next stage.

Tempering

Heat treatment transforms the steel, giving it the hardness and flexibility professional tools require.

Controlled Heating Tools are heated to specific temperatures based on their intended use—scissors require different hardness than razors or nail nippers.

Rapid Cooling (Quenching) Heated tools are rapidly cooled in specialized oil or water baths, locking in hardness and creating a resilient molecular structure.

Stress Relief A secondary heating process removes internal stresses, preventing warping and ensuring long-term stability and performance.

Polishing & Initial Quality Check

Rough surfaces are refined through multi-stage polishing, preparing tools for finishing treatments.

Surface Grinding Coarse abrasives remove forging marks and create smooth, even surfaces across all tool components.

Progressive Polishing Multiple polishing stages using finer abrasives gradually increase surface smoothness and bring out the steel’s natural luster.

Dimensional Inspection Tools are measured against specifications to verify proper dimensions, blade alignment, and overall geometry before finishing.

Coloring & Surface Finishing

Protective and aesthetic coatings are applied to enhance appearance, durability, and corrosion resistance.

Paper Coating A specialized paper-based protective layer that provides temporary protection during storage and shipping.

Powder Coating Durable polymer powder is electrostatically applied and heat-cured, creating a tough, colorful finish resistant to chips and scratches.

Plasma Coating Advanced plasma technology deposits ultra-thin protective layers that enhance hardness and reduce friction during cutting.

Ceramic Coating High-temperature ceramic finishes provide superior heat resistance and create sleek, professional appearances in various colors.

Electroplating Metal ions are deposited through electrolysis, creating mirror-like chrome, gold, or titanium finishes that resist tarnishing and corrosion.

Scissor Assembly

Individual components are expertly assembled into fully functional cutting instruments.

Pivot Installation Precision-machined pivot screws or rivets are installed, creating the perfect tension between blades for smooth opening and closing.

Blade Alignment Expert technicians carefully align cutting edges to ensure blades meet perfectly along their entire length without gaps or overlap.

Tension Adjustment Each scissor is individually tested and adjusted to achieve optimal cutting resistance—firm enough for control, smooth enough for comfort.

Sharpening

Cutting edges are honed to razor-sharp precision using specialized grinding techniques.

Edge Grinding Industrial grinding wheels create the initial cutting bevel at precise angles optimized for different cutting tasks.

Fine Honing Leather stropping wheels with polishing compounds refine the edge to surgical sharpness, removing microscopic burrs.

Convex Edge Formation Premium scissors receive convex (clamshell) edge grinding, allowing smoother cutting action preferred by professional stylists.

Final Quality Check

Every instrument undergoes comprehensive inspection before packaging to ensure it meets our exacting standards.

Functional Testing Scissors are tested on various materials, razors are checked for blade exposure and smoothness, nail tools are tested for grip and cutting performance.

Visual Inspection Trained quality control specialists examine every surface for scratches, coating imperfections, or alignment issues.

Measurement Verification Final dimensional checks confirm all specifications are met, ensuring consistency across your entire order.

Performance Certification Tools that pass all tests receive our quality approval and are ready for custom branding if requested.

Custom Branding & Packaging

Your approved tools are branded with your logo and packaged according to your specifications.

Logo Application Laser engraving, etching, or printing applies your brand identity permanently and professionally to each tool.

Protective Packaging Individual tools are wrapped in protective materials to prevent damage during shipping and storage.

Custom Packaging Options We offer branded boxes, pouches, display cases, or bulk packaging based on your retail or distribution needs.

Final Documentation Each shipment includes product specifications, quality certificates, and care instructions for your customers.

Experience the SurgiQat Difference

See how our precision manufacturing process can elevate your salon's tool quality while reducing costs. Schedule a 10-minute consultation to discuss custom options, pricing, and how we can support your business.

Schedule a Meeting | Request Samples | Get a Quote